Filament Nonwoven Geotextile

Custom, Wholesale Manufacturer Global shipping

Mainly Features

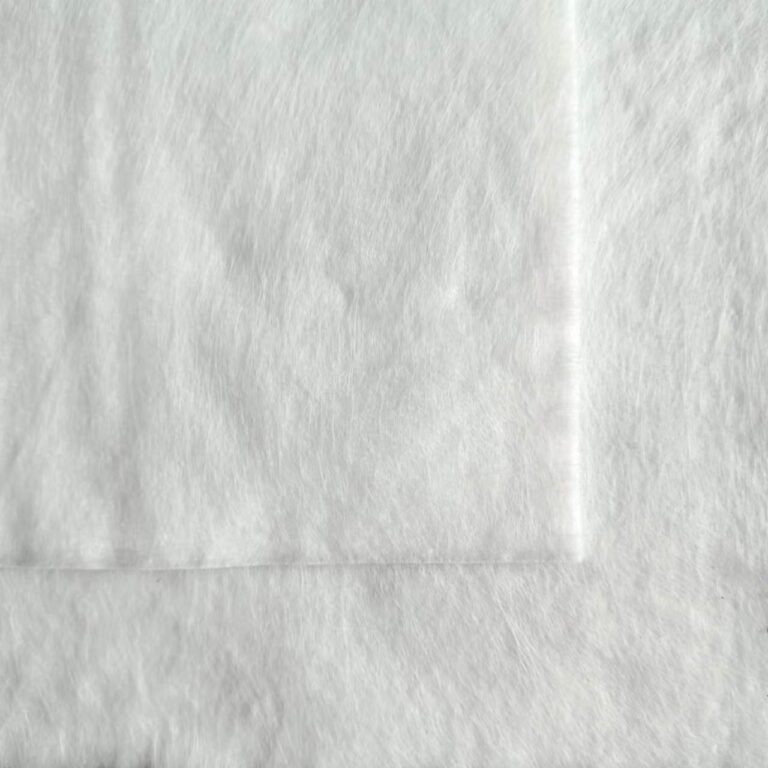

Polyester or Polypropylene

- Nonwoven needle punched

Continous Filament fiber

White color

Filtration

Water permeability

Separation

Reinforcement

Protection

Cost effective replace of Polyfelt TS Maccaferri Tencate Geotextile Bidim cloth

Advantage and Function

- 1. High strength – PET filament nonwoven geotextile uses polyester fiber as raw material and forms uniform fabric through non-woven method. Polyester fiber itself has the characteristics of high modulus and low elongation, which makes PET filament non-woven geotextile have excellent tensile strength and tear strength. In addition, due to the stable fiber structure and strong durability, it can maintain a long service life even in extreme external environments, such as high temperature, ultraviolet radiation or chemical corrosion, and is not easy to degrade or damage.

- 2. Corrosion resistance -Made of polyester (PET) fiber, this high molecular polymer has excellent chemical stability. Polyester fiber has natural resistance to most chemicals and can withstand soil environments with different pH values and erosion by a variety of chemicals such as acids, alkalis, salts, etc.Very suitable for chemical areas or projects containing corrosive substances。

- 3. Good water permeability – The filament fibers are made through a non-woven process. This non-woven structure creates a large number of micropores inside the material, which are the key to water permeability. The microporous structure allows water to pass freely while preventing soil particles from being lost with water, achieving ideal filtration and drainage effects.

- 4. Anti-microbial properties – PET (polyester) is the main raw material for making filament non-woven geotextiles. This high molecular polymer itself has high chemical stability and is not easily decomposed by microorganisms such as bacteria and fungi. Polyester fiber does not provide the nutrient source required for microbial growth, so it is naturally difficult to support the growth and reproduction of microorganisms.

- 5. Convenient construction -The material is light and soft, it is easy to transport and install.It has excellent mechanical properties and dimensional stability. These characteristics allow the material to be quickly deployed and fixed during the laying process, without the need for complex pretreatment or special laying techniques. In addition, due to its durability and tear resistance, it can maintain integrity even in harsh construction environments, reducing material loss and replacement frequency during construction.

- 6. Complete specifications – Width 1.0m to 6.0 m, unit area mass 150 gsm(4 oz) to 1000 gsm(36 oz), support customized.

- 7. High standard– We Follow international standards, with the same quality, it has a cost advantage and is a good choice to replace international brand geotextiles. Exported to the United States, Canada, Australia, Singapore, New Zealand, South Africa, Southeast Asia, South American countries, etc.

- Water Permeability

- Filtration

- Separation

- Reinforcement

- Protection

Application

Polyester needle punched non-woven geotextile fabric is a widely used geosynthetics material. It is widely used in railway roadbed reinforcement, landscape, highway pavement maintenance, sports halls, dam protection, hydraulic construction isolation, tunnels, coastal beaches, reclamation, environmental protection and other projects.

- 1. Filter materials for soil separation;

- 2. Drainage materials for reservoirs and mines, and drainage materials for high-rise building foundations;

- 3. Anti-scouring materials for river embankments and slope protection;

- 4. Reinforcement materials for railway, highway, and airport runway subgrades, and reinforcement materials for road construction in swamp areas;

- 5. Anti-frost and anti-freeze insulation materials;

- 6. Anti-cracking materials for asphalt pavement.

For examples

- 1. Reinforcement in retaining wall backfill, or for anchoring retaining wall panels. Construction of wrapped retaining walls or bridge abutments.

- 2. Reinforcement of flexible pavement, repair of cracks on the road, and prevention of crack reflection on the pavement.

- 3. Increase the stability of gravel slopes and reinforced soil, prevent soil erosion and freezing damage of soil at low temperatures.

- 4. Isolation layer between road ballast and roadbed, or between roadbed and soft foundation.

- 5. Isolation layer between artificial fill, rock pile or material field and foundation, isolation between different frozen soil layers, anti-filtration and reinforcement.

- 6. Filter layer of the initial upstream dam surface of ash storage dam or tailings dam, and filter layer of drainage system in retaining wall backfill.

- 7. Filter layer around drainage pipe-drainage culvert or gravel drainage culvert.

- 8. Filter layer of wells, pressure relief wells or inclined pressure pipes in water conservancy projects.

- 9. Geotextile isolation layer between highways, airports, railway tracks and artificial rockfill and foundation.

- 10. Vertical or horizontal drainage inside earth dams, buried in the soil to dissipate pore water pressure.

- 11. Drainage behind the anti-seepage geomembrane or under the concrete face in earth dams or earth embankments.

- 12. Remove seepage around tunnels, reduce the external water pressure on the lining and seepage around buildings.

- 13. Drainage of artificial fill foundations and sports fields.

- 14. Highways include temporary roads, railways, embankments, earth-rock dams, airports, sports fields and other projects to strengthen weak foundations.

How to install

Installation and laying method of filament non-woven geotextile fabric:

- 1. Check the base layer to see if it is flat and solid. If there are foreign objects, they should be properly handled.

- 2. Laying, manual or mechanical rolling, the surface of the fabric should be flat, and a proper deformation margin should be left. Anchor one end of the non-woven geotextile fabric, then roll the roll, and keep the non-woven geotextile fabric properly taut.

- 3. Overlap, the installation of non-woven geotextile fabrics usually uses natural overlap, stitching and welding.

Non-woven geotextile fabrics that are exposed for a long time should be welded or stitched. The overlap should be flat and moderately tight.

The minimum width is 15cm when stitching, 20cm when naturally overlapping, and 20cm when hot air welding. - 3.1 For the sewing of non-woven geotextile fabrics, all sewing must be done continuously (for example, spot sewing is not allowed), the minimum stitch distance from the selvedge (exposed edge of the material) is at least 25mm, and the sewing thread of the same quality as the non-woven geotextile fabric should be used, and the sewing thread should be made of a material with stronger resistance to chemical damage and UV exposure. Use a special sewing machine for double-line sewing connection.

- 3.2 Hot air welding is the preferred connection method for filament non-woven geotextile fabrics, that is, use a hot air gun to instantly heat the connection of the two pieces of fabric to a high temperature, so that part of it reaches a molten state, and immediately use a certain external force to firmly bond them together. In humid (rainy and snowy) weather, when hot bonding cannot be performed, the non-woven geotextile fabric should be sewn.

- 4. After laying, check whether the non-woven geotextile fabric is laid flat, whether there are defects, and make timely corrections.

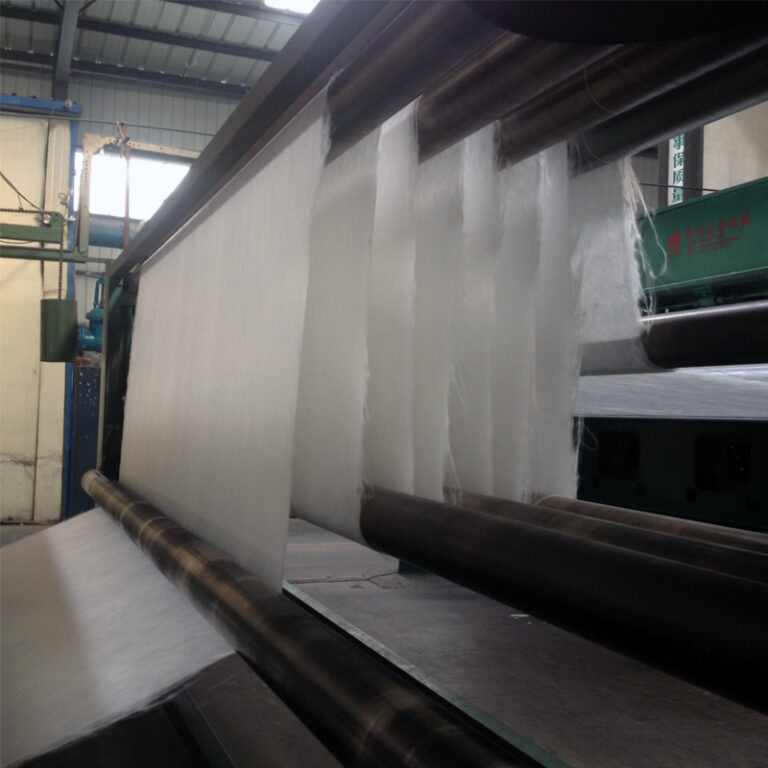

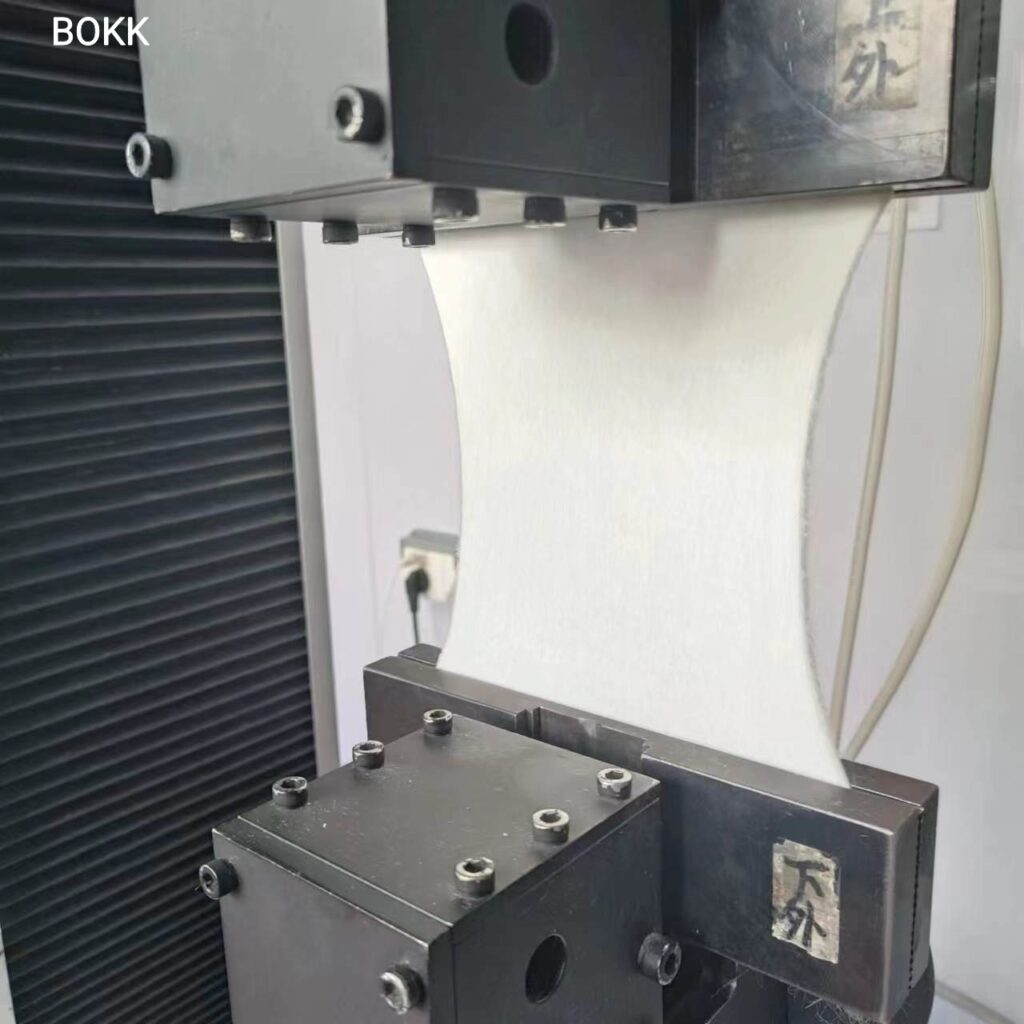

Production

Needle punched non woven filament geotextile is made from virgin PET(polyester) or PP (polypropylene) chips, the continuous filament was extruded from synthetic chips by machine directly by spun bond process, and then needlepunch together to get the stable 3D with higher strength fabric. The finished product is in cloth form, generally 4 meters to 6 meters width and 50m to 150m length.

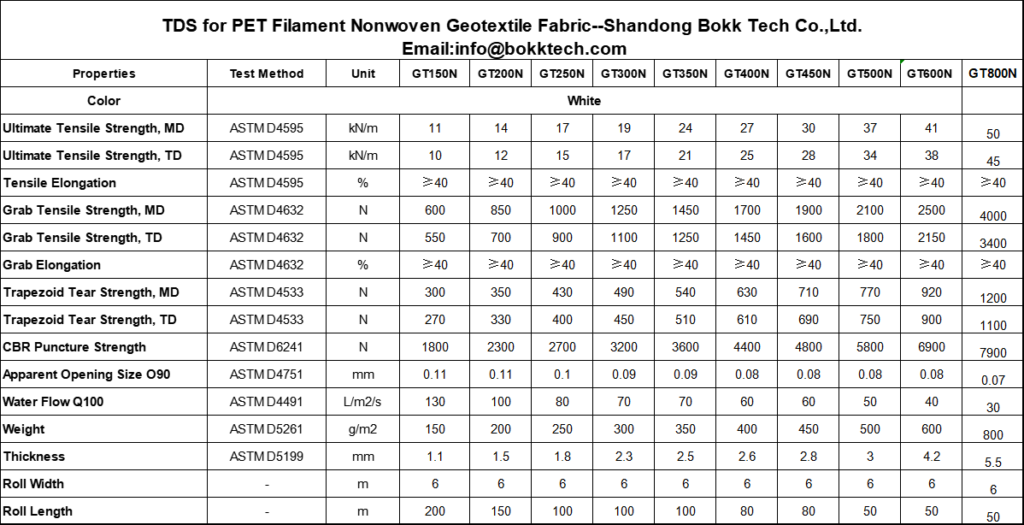

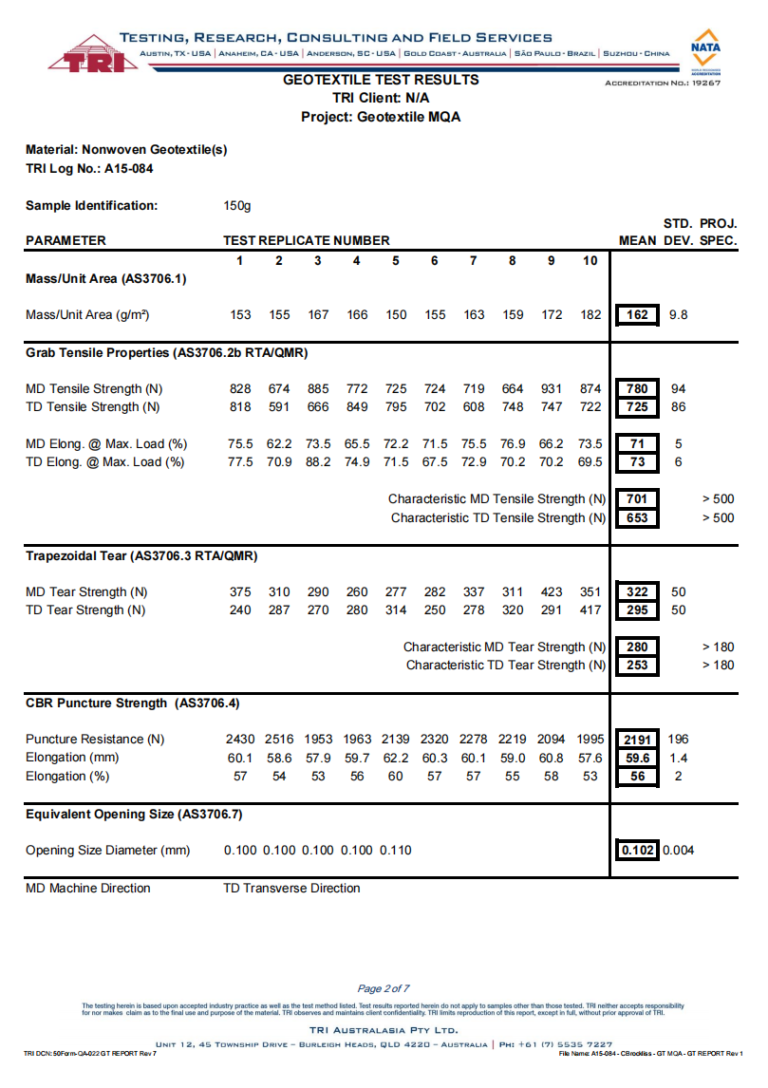

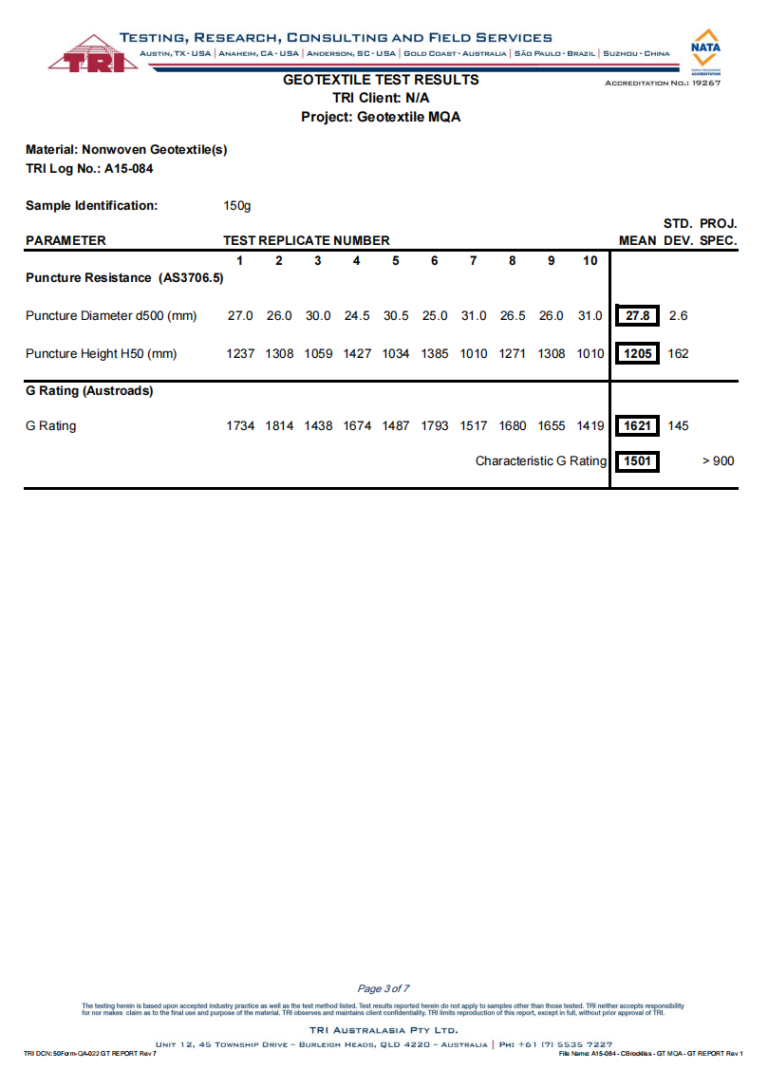

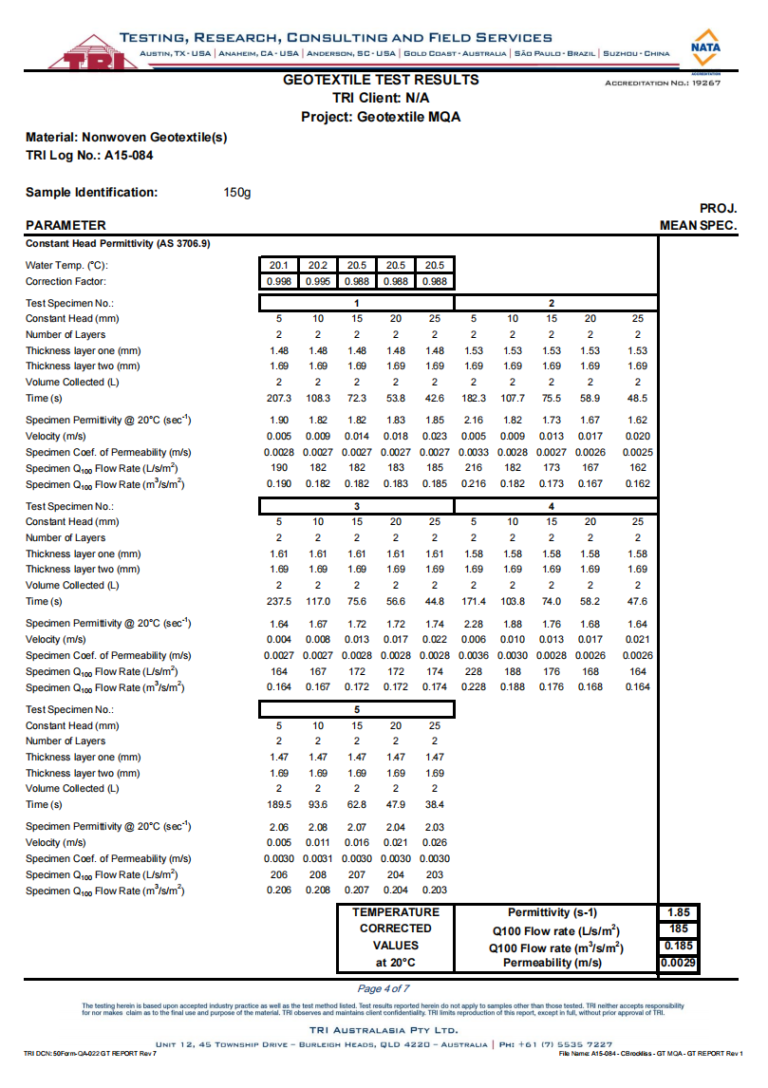

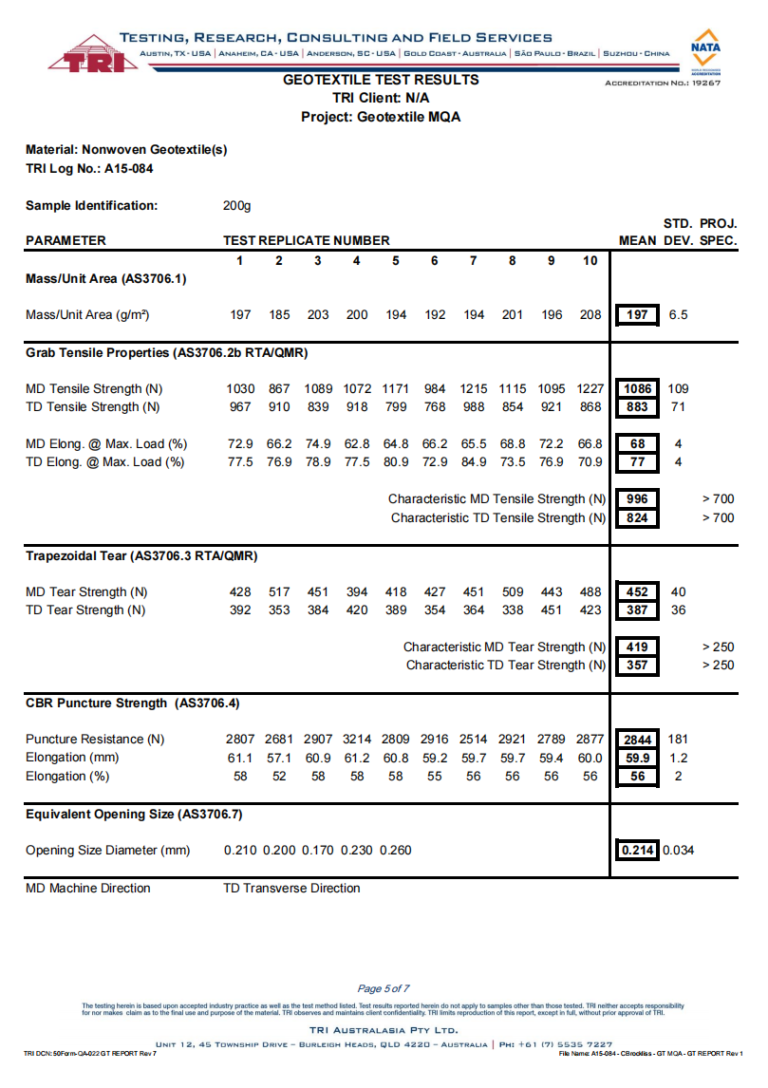

Technical Data Sheet

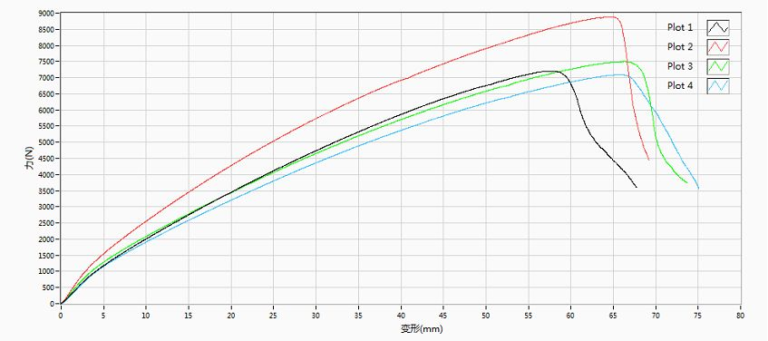

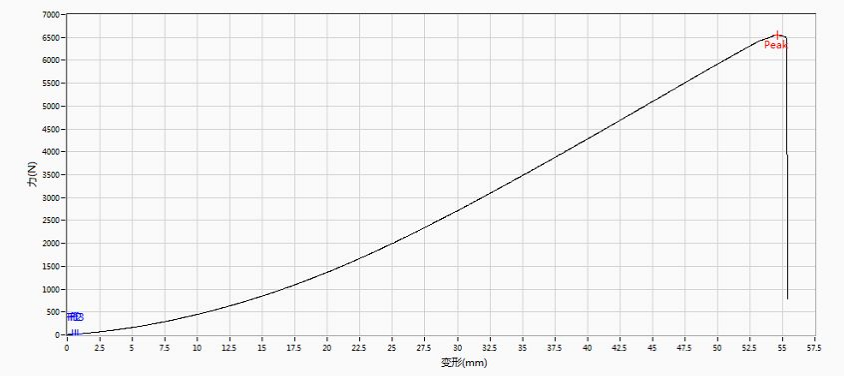

Quality Control

Advance testing equipment make sure every batch filament Nonwoven Geotextile products meet international standard, follow ASTM test method.

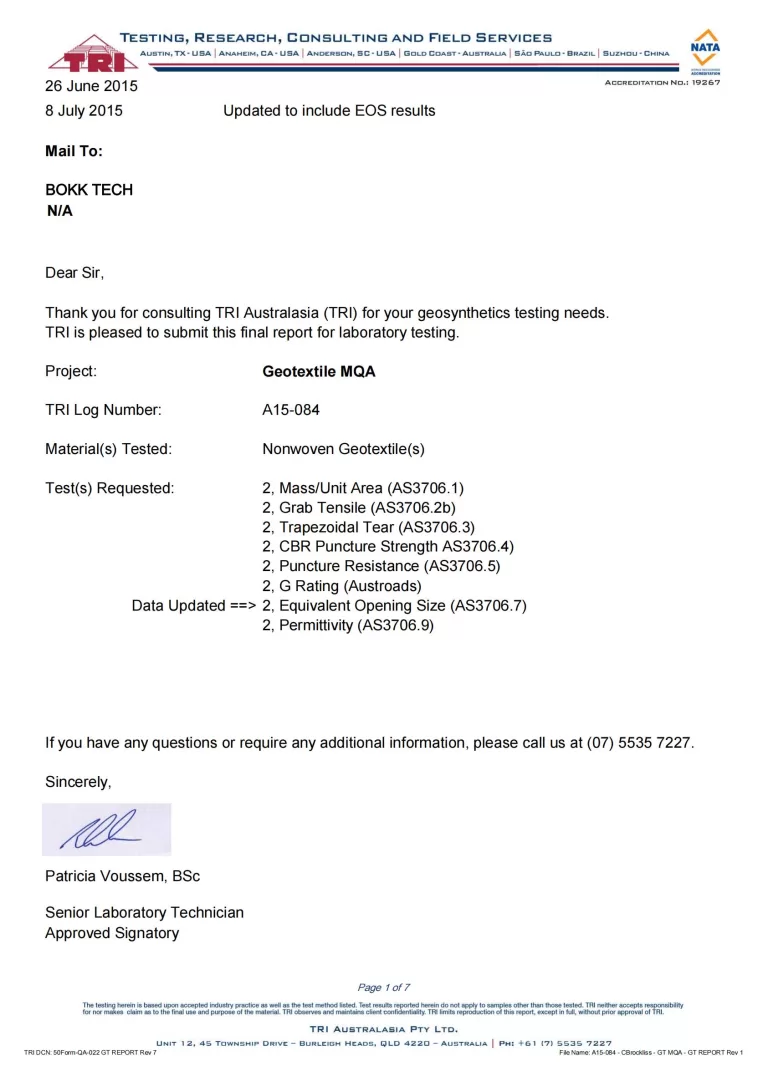

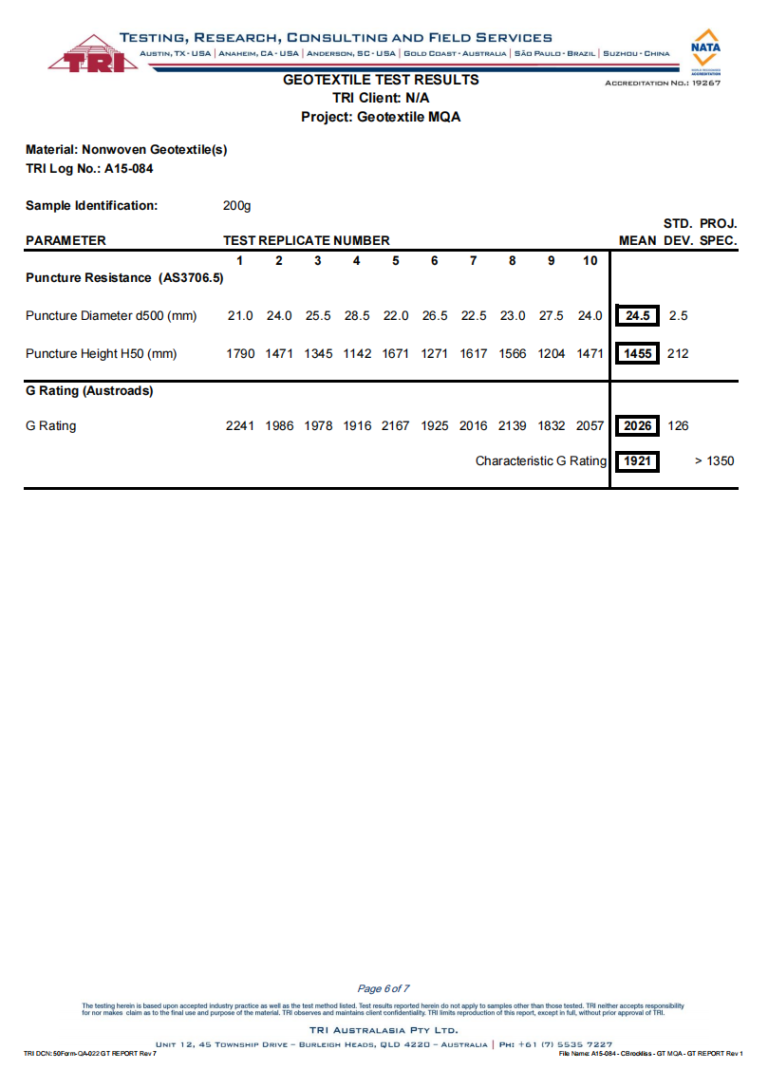

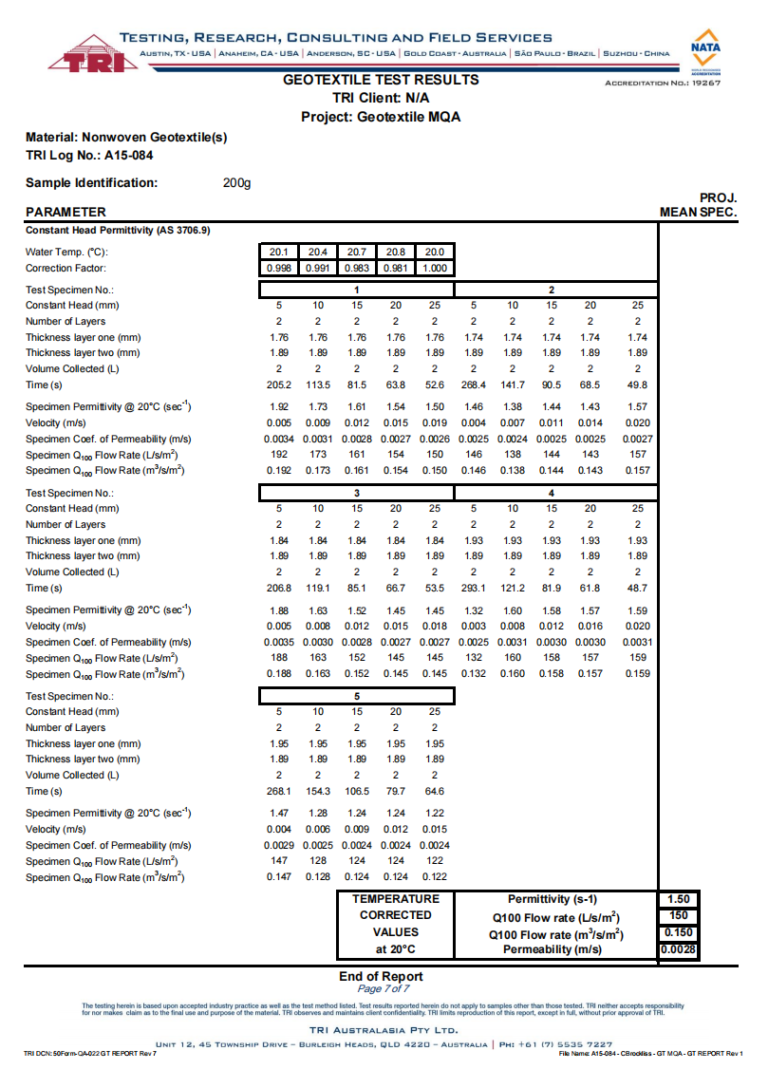

Test Report Certificate-Third Party Agency TRI

Package and Loading

High-quality geotextile, professional packaging, affordable transportation!

Rolled and packaged: Our geotextiles are rolled and packaged, containing an entire reinforced roll core and covered with PE plastic film to effectively prevent stains. Not only does this protect the integrity of your product, it also makes your goods easier to handle and store.

Save shipping costs: Roll packaging not only saves space, but also allows you to load more products and reduce transportation costs. We understand our customers’ concerns about shipping costs, so our packaging is designed to minimize your shipping expenses.

Market competitiveness: We not only provide high-quality geotextiles, but also consider every detail for you, from packaging to transportation, to make your business more competitive.

- Support customized package