When embarking on a landscaping or civil engineering project, the choice of materials can make all the difference, especially when it comes to geotextiles. Woven and nonwoven geotextiles each bring unique properties that can significantly impact your project’s success. But how do you know which one is right for your specific needs? This guide unpacks the fundamental differences between these two types of geotextiles, exploring their construction, applications, and benefits. Whether you’re looking to enhance soil stability, manage drainage, or control erosion, understanding the strengths and limitations of woven versus nonwoven options is essential for making an informed decision. Join us as we delve into the world of geotextiles and discover the perfect solution tailored to your project goals.

What are Woven Geotextiles?

Woven geotextiles are manufactured through a meticulous process that involves weaving individual yarns into a tight, flat fabric. The key component in woven geotextiles is the yarn, which is typically made from synthetic materials such as polypropylene or polyester. These materials are chosen for their durability, resistance to environmental stresses, and longevity. The weaving process results in a fabric that possesses high tensile strength and low elongation, making it ideal for applications that require robust reinforcement and support.

The interlacing pattern of the yarns in woven geotextiles creates a grid-like structure, which is instrumental in providing stability and load distribution. This grid structure allows the fabric to maintain its integrity under heavy loads, making it highly effective in soil stabilization and separation applications. Furthermore, the tight weave minimizes the passage of fine particles, ensuring that soil and other materials are kept in place, which is particularly advantageous in applications where erosion control is a priority.

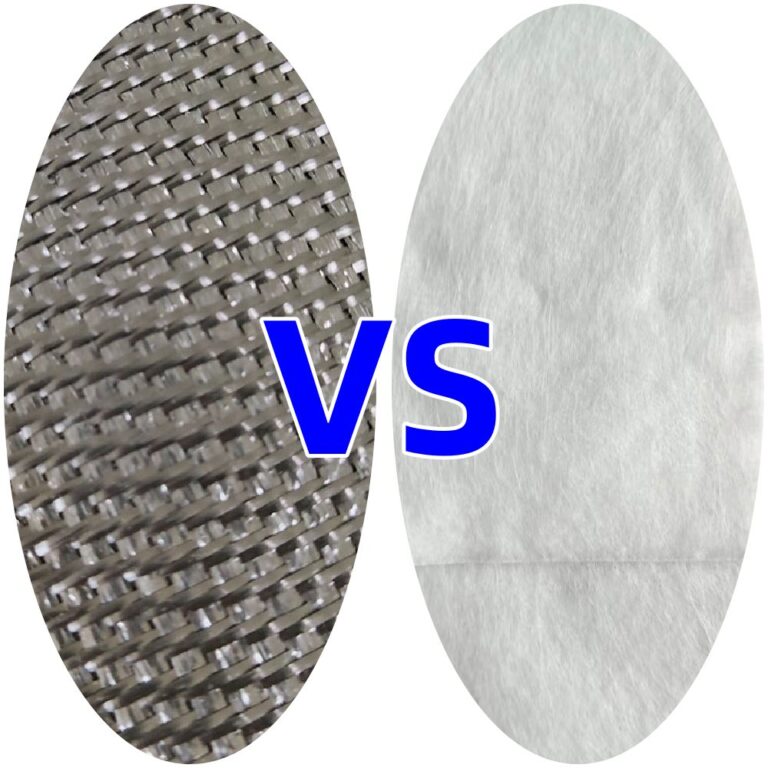

In terms of physical appearance, woven geotextiles typically have a smooth and uniform texture, which can be easily identified by their distinct weaving pattern. This characteristic not only contributes to their mechanical strength but also facilitates ease of handling and installation. The consistency in texture ensures that the fabric can be laid out smoothly, providing an even and stable foundation for various construction and landscaping projects.

What are Nonwoven Geotextiles?

Nonwoven geotextiles, on the other hand, are produced using a different manufacturing method that does not involve weaving. Instead, these geotextiles are created through a process known as needle punching or thermal bonding, where fibers are entangled or bonded together to form a fabric. The fibers used in nonwoven geotextiles are typically made from synthetic materials such as polypropylene or polyester, similar to their woven counterparts. However, the resulting fabric has a distinctly different structure and set of properties.

The needle punching process involves mechanically interlocking the fibers using a series of barbed needles, which creates a fabric with a high degree of porosity and flexibility. This structure allows nonwoven geotextiles to exhibit excellent water permeability, making them highly effective in drainage and filtration applications. The porous nature of the fabric enables water to pass through while trapping fine particles, preventing soil erosion and promoting efficient water management.

In addition to their permeability, nonwoven geotextiles are known for their ability to conform to irregular surfaces and provide cushioning and protection. This makes them particularly well-suited for applications where flexibility and adaptability are crucial, such as in landscaping, road construction, and erosion control. The fabric’s soft and pliable texture ensures that it can be easily manipulated to fit various contours and shapes, providing a tailored solution for each project.

While nonwoven geotextiles may not possess the same level of tensile strength as woven geotextiles, their unique properties make them indispensable in scenarios where drainage, filtration, and adaptability are paramount. The combination of high permeability and flexibility ensures that nonwoven geotextiles can address a wide range of challenges in construction and environmental management.

Key Differences Between Woven and Nonwoven Geotextiles

The primary distinction between woven and nonwoven geotextiles lies in their manufacturing processes and resulting structural properties. Woven geotextiles are created through a weaving process, resulting in a fabric that is characterized by a grid-like structure with high tensile strength and low elongation. This makes them particularly effective in applications that require reinforcement, load distribution, and soil stabilization. The tight weave also minimizes the passage of fine particles, making woven geotextiles suitable for erosion control and separation tasks.

In contrast, nonwoven geotextiles are produced through needle punching or thermal bonding, which creates a fabric with a high degree of porosity and flexibility. This manufacturing method results in a material that excels in water permeability and filtration, making nonwoven geotextiles ideal for drainage and erosion control applications. Additionally, the soft and pliable texture of nonwoven geotextiles allows them to conform to irregular surfaces and provide cushioning and protection, making them versatile for a variety of projects.

Another key difference between woven and nonwoven geotextiles is their physical appearance and texture. Woven geotextiles have a smooth and uniform texture with a distinct weaving pattern, which contributes to their mechanical strength and ease of handling. Nonwoven geotextiles, on the other hand, have a more fibrous and porous texture, which enhances their permeability and adaptability. This distinction in texture is not just cosmetic but also influences the performance and suitability of each type of geotextile for specific applications.

The differences in tensile strength and permeability between woven and nonwoven geotextiles also play a crucial role in determining their respective advantages and applications. Woven geotextiles, with their high tensile strength, are more suited for applications that require robust support and reinforcement. Nonwoven geotextiles, with their excellent permeability, are better suited for drainage, filtration, and erosion control. Understanding these key differences is essential for selecting the right type of geotextile for your project, ensuring that you achieve the desired outcomes in terms of stability, drainage, and protection.

Advantages of Woven Geotextiles

One of the primary advantages of woven geotextiles is their exceptional tensile strength. This property makes them ideal for applications that require reinforcement and stabilization, such as in road construction, retaining walls, and embankments. The high tensile strength ensures that the fabric can withstand significant loads and stresses, providing a stable and durable foundation. This is particularly important in projects where soil stability and load distribution are critical to the longevity and safety of the structure.

Another advantage of woven geotextiles is their ability to effectively separate different layers of soil and aggregate materials. The tight weave of the fabric prevents the mixing of fine particles with coarse materials, maintaining the integrity of each layer. This separation function is crucial in preventing contamination and ensuring the proper functioning of drainage systems. In addition, woven geotextiles can help prevent rutting and deformation of the soil, which can occur when different layers intermingle under heavy loads.

Woven geotextiles also offer excellent resistance to environmental factors such as UV radiation, chemical exposure, and biological degradation. The synthetic materials used in their construction, such as polypropylene and polyester, are chosen for their durability and resistance to these stresses. This ensures that woven geotextiles can perform effectively over long periods, even in harsh environmental conditions. The longevity and reliability of woven geotextiles make them a cost-effective choice for projects that require long-term stability and performance.

Advantages of Nonwoven Geotextiles

Nonwoven geotextiles offer several advantages that make them highly suitable for a variety of applications. One of the most significant benefits is their excellent water permeability. The porous structure of nonwoven geotextiles allows water to pass through while trapping fine particles, making them highly effective in drainage and filtration applications. This property is particularly useful in managing surface water, reducing erosion, and preventing the buildup of hydrostatic pressure in soil structures.

Another advantage of nonwoven geotextiles is their flexibility and adaptability. The soft and pliable texture of these fabrics allows them to conform to irregular surfaces and contours, providing a tailored fit for each project. This adaptability is crucial in applications such as landscaping, where the geotextile needs to conform to the natural shape of the terrain. The ability to mold to various shapes and surfaces also makes nonwoven geotextiles suitable for use in road construction, where they can provide cushioning and protection for underlying layers.

Nonwoven geotextiles are also known for their ability to provide effective erosion control. The fabric’s high permeability and filtration capabilities help prevent the displacement of soil particles, reducing the risk of erosion. This is particularly important in areas prone to heavy rainfall or water flow, where controlling erosion is essential for maintaining the stability and integrity of the landscape. The combination of permeability, flexibility, and erosion control makes nonwoven geotextiles a versatile and valuable tool in a wide range of construction and environmental management projects.

Applications of Woven Geotextiles

Woven geotextiles are widely used in applications that require soil stabilization, reinforcement, and separation. One of the most common uses is in road construction, where woven geotextiles are placed between the subgrade and aggregate layers to improve load distribution and prevent rutting. The high tensile strength of woven geotextiles ensures that the road remains stable and durable, even under heavy traffic loads. This application helps extend the lifespan of the road and reduces maintenance costs.

Another important application of woven geotextiles is in the construction of retaining walls and embankments. In these projects, woven geotextiles are used to reinforce the soil and prevent erosion. The fabric’s ability to provide effective separation and load distribution is crucial in maintaining the stability of these structures. By preventing the mixing of different soil layers and ensuring proper drainage, woven geotextiles help prevent the failure of retaining walls and embankments, contributing to the overall safety and longevity of the project.

Woven geotextiles are also used in various other applications, such as in the construction of landfills, drainage systems, and erosion control projects. In landfills, woven geotextiles are used as a separation layer to prevent the mixing of waste materials with the surrounding soil. In drainage systems, they help maintain the integrity of the drainage layers by preventing the clogging of drainage pipes. In erosion control projects, woven geotextiles provide a stable foundation that helps prevent soil erosion and promotes vegetation growth. These diverse applications highlight the versatility and effectiveness of woven geotextiles in addressing a wide range of construction and environmental challenges.

Applications of Nonwoven Geotextiles

Nonwoven geotextiles are highly valued for their permeability, flexibility, and filtration capabilities, making them ideal for a variety of applications. One of the primary uses of nonwoven geotextiles is in drainage and filtration systems. The porous structure of the fabric allows water to pass through while trapping fine particles, preventing clogging and ensuring efficient drainage. This application is particularly important in managing surface water and reducing the risk of erosion and water damage.

In landscaping projects, nonwoven geotextiles are used to prevent soil erosion and promote healthy vegetation growth. The fabric’s ability to conform to irregular surfaces and provide effective filtration makes it an excellent choice for stabilizing slopes, controlling runoff, and protecting plant roots. By preventing the displacement of soil particles and promoting proper water management, nonwoven geotextiles help maintain the stability and integrity of landscaped areas.

Nonwoven geotextiles are also used in road construction, where they provide cushioning and protection for underlying layers. The fabric’s flexibility allows it to conform to the natural contours of the terrain, providing a stable foundation for the road. In addition, nonwoven geotextiles help prevent the mixing of different soil layers, reducing the risk of rutting and deformation. This application is particularly important in areas with challenging soil conditions, where maintaining the stability and durability of the road is crucial.

Factors to Consider When Choosing Geotextiles for Your Project

When selecting the right geotextile for your project, several factors need to be considered to ensure optimal performance and outcomes. One of the primary considerations is the specific application and requirements of your project. Determine whether you need reinforcement, separation, drainage, filtration, or erosion control, as each type of geotextile offers distinct advantages in these areas. Understanding the primary function you need will help you choose between woven and nonwoven geotextiles.

Another critical factor to consider is the environmental conditions and stresses that the geotextile will be exposed to. Evaluate the potential for UV radiation, chemical exposure, and biological degradation, and choose a geotextile made from materials that can withstand these conditions. For projects that require long-term performance and durability, woven geotextiles may be more suitable due to their resistance to environmental factors. For applications where permeability and flexibility are more important, nonwoven geotextiles may be the better choice.

The specific soil and terrain conditions of your project site should also be taken into account. Assess the soil type, load requirements, and potential for erosion, and select a geotextile that can effectively address these challenges. For example, if your project involves soft or unstable soil, a woven geotextile with high tensile strength may be necessary for soil stabilization. If you are dealing with areas prone to heavy rainfall or water flow, a nonwoven geotextile with excellent permeability and filtration capabilities may be the best option.

Cost and budget considerations are also important when choosing geotextiles. While both woven and nonwoven geotextiles offer cost-effective solutions, the specific needs of your project and the desired performance outcomes should guide your decision. Evaluate the long-term benefits and potential maintenance costs associated with each type of geotextile, and choose the one that provides the best value for your investment.

Conclusion: Making the Right Choice for Your Project

In conclusion, understanding the differences between woven and nonwoven geotextiles is essential for making an informed decision that aligns with your project goals. Woven geotextiles, with their high tensile strength and ability to provide reinforcement and separation, are ideal for applications that require robust support and soil stabilization. Nonwoven geotextiles, with their excellent permeability, flexibility, and filtration capabilities, are well-suited for drainage, erosion control, and adaptability to irregular surfaces.

When choosing the right geotextile for your project, consider the specific application, environmental conditions, soil and terrain characteristics, and budget constraints. By carefully evaluating these factors, you can select the geotextile that best meets your needs and ensures the success and  longevity of your project. Whether you are working on road construction, landscaping, erosion control, or any other application, the right geotextile can make all the difference in achieving your desired outcomes.