In the ever-evolving landscape of sustainable construction, non-woven geotextiles emerge as a game-changing solution, bridging the gap between environmental responsibility and robust engineering. These innovative materials, crafted from synthetic fibers, offer an array of benefits that enhance both performance and longevity in various applications. From soil stabilization to erosion control, non-woven geotextiles provide essential support while minimizing the ecological footprint of construction projects. As more industries shift towards sustainable practices, understanding the advantages of these geotextiles becomes crucial for architects, engineers, and contractors alike. This comprehensive guide will delve into the numerous benefits of non-woven geotextiles, illuminating their role in promoting sustainability, facilitating better drainage, and ensuring the durability of infrastructures. Discover how integrating these materials can not only elevate your projects but also contribute to a greener future in construction. Join us as we unveil the transformative potential of non-woven geotextiles in building a sustainable tomorrow.

What are Non-Woven Geotextiles?

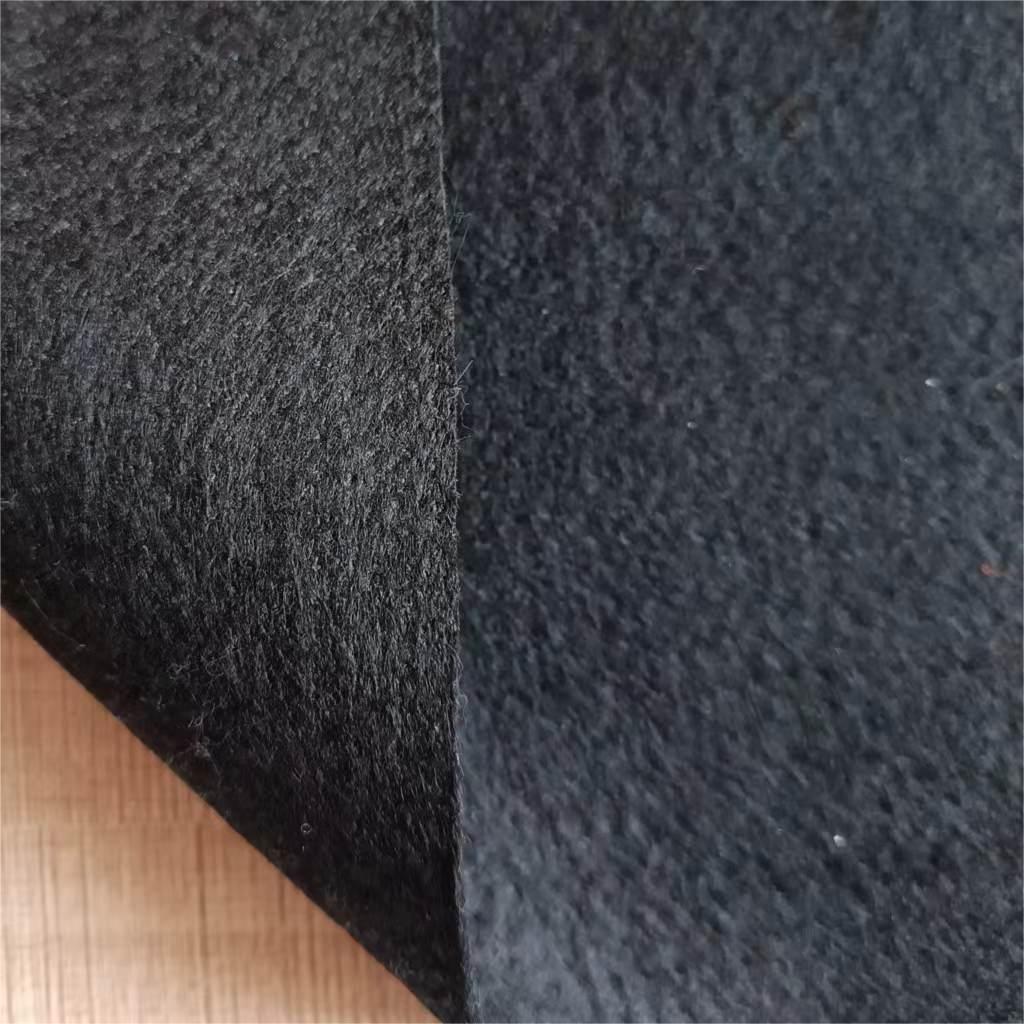

Non-woven geotextiles are a type of fabric produced using synthetic fibers that are bonded together through mechanical, chemical, or thermal processes. Unlike their woven counterparts, which are created by interlacing threads in a traditional weaving pattern, non-woven geotextiles are formed through a mat of fibers that are randomly oriented and then consolidated into a stable matrix. This structure imparts unique properties to non-woven geotextiles, including high permeability, flexibility, and tensile strength, making them suitable for a variety of engineering applications. These materials are manufactured in various thicknesses and densities, allowing for customization to meet specific project requirements.

The production process of non-woven geotextiles typically involves several steps starting from the selection of polymer granules, which are melted and extruded into fine filaments. These filaments are then laid down to form a web, which is subsequently bonded through needlepunching, heat, or chemical adhesives to achieve the desired characteristics. The result is a versatile material that offers advantages over traditional construction materials in terms of both performance and sustainability. These fibers are often made from polyester or polypropylene, which provide resistance to biological and chemical degradation, thus ensuring longevity in demanding environments.

The versatility of non-woven geotextiles means they can be used in a wide range of applications, from road construction and embankment stabilization to drainage systems and erosion control. Their ability to filter, separate, reinforce, protect, and drain makes them indispensable in modern construction projects. As the construction industry seeks more sustainable solutions, the role of non-woven geotextiles has become increasingly prominent. Their adaptability and eco-friendly benefits make them a preferred choice for many engineers and project managers looking to balance performance with environmental responsibility.

Key Benefits of Non-Woven Geotextiles in Construction

One of the primary benefits of non-woven geotextiles in construction is their ability to enhance soil stabilization and ground support. When applied to soil, these materials prevent the mixing of different soil layers, maintaining the integrity of the ground structure. This is particularly crucial in applications such as road construction, where a stable foundation is necessary to support heavy traffic loads. By providing a barrier that separates soil layers, non-woven geotextiles help to distribute loads evenly, reducing the risk of settlement and deformation.

Another significant advantage of non-woven geotextiles is their exceptional drainage capabilities. The porous structure of these fabrics allows water to pass through while trapping soil particles, thus preventing erosion and maintaining soil stability. This feature is vital in areas prone to heavy rainfall or flooding, where effective water management is critical. Non-woven geotextiles can be used in drainage systems to facilitate the movement of water away from structures, preventing waterlogging and associated damage. Their use in such systems can enhance the longevity and performance of construction projects by mitigating the risk of water-induced deterioration.

Non-woven geotextiles also offer benefits in terms of erosion control. Their ability to reinforce soil and provide a protective layer makes them ideal for use in slopes, embankments, and shorelines. By securing the soil surface, these materials prevent the detachment and transport of soil particles caused by wind and water. This not only helps to maintain the landscape but also protects against the loss of fertile topsoil, which is crucial for vegetation growth. In addition to these functional benefits, the use of non-woven geotextiles can also contribute to cost savings by reducing the need for frequent maintenance and repairs.

Environmental Impact and Sustainability

The construction industry is under increasing pressure to adopt sustainable practices, and non-woven geotextiles play a pivotal role in this shift. One of the key environmental benefits of these materials is their ability to reduce the ecological footprint of construction projects. Made from synthetic fibers such as polyester and polypropylene, non-woven geotextiles are designed to withstand harsh environmental conditions without degrading. This durability means that they can be used for extended periods, reducing the need for frequent replacements and minimizing waste.

Moreover, the production of non-woven geotextiles often involves the use of recycled materials, further enhancing their sustainability credentials. Many manufacturers are now incorporating post-consumer and post-industrial waste into their production processes, thereby diverting waste from landfills and reducing the demand for virgin materials. This not only conserves natural resources but also reduces the energy consumption and greenhouse gas emissions associated with the production of new materials. By choosing non-woven geotextiles made from recycled content, construction projects can significantly lower their environmental impact.

In addition to their material composition, non-woven geotextiles contribute to sustainability through their functional benefits. Their ability to enhance soil stability and prevent erosion reduces the need for chemical soil stabilizers and other environmentally harmful interventions. Furthermore, their drainage capabilities help to manage water efficiently, reducing the risk of waterlogging and associated issues such as soil salinization and habitat destruction. By promoting the efficient use of natural resources and minimizing environmental degradation, non-woven geotextiles support the broader goals of sustainable development in the construction industry.

Applications of Non-Woven Geotextiles in Various Projects

Non-woven geotextiles find extensive applications in road construction, where they are used to enhance the stability and longevity of pavements. By separating the subgrade from the aggregate layers, these materials prevent the intermixing of different soil types, ensuring a stable foundation. This separation layer also helps to distribute loads more evenly, reducing the risk of rutting and deformation under heavy traffic. Additionally, the drainage capabilities of non-woven geotextiles prevent water accumulation within the pavement layers, which can lead to premature failure. Their use in road construction not only improves performance but also reduces maintenance costs by extending the lifespan of the pavement.

In the realm of erosion control, non-woven geotextiles are used to protect slopes, embankments, and shorelines from the erosive forces of wind and water. When applied to these areas, they provide a protective layer that reinforces the soil and prevents the detachment of soil particles. This is particularly important in areas prone to heavy rainfall or wave action, where erosion can lead to significant land loss and damage to infrastructure. By stabilizing the soil, non-woven geotextiles help to maintain the integrity of the landscape and prevent the loss of valuable topsoil. They are also used in conjunction with vegetation to promote the establishment of plant roots, which further enhances soil stability.

Non-woven geotextiles are also widely used in drainage systems, where they facilitate the efficient movement of water away from structures. Their porous structure allows water to pass through while trapping soil particles, preventing clogging and ensuring the continuous flow of water. This makes them ideal for use in subsurface drainage systems, where they can help to manage water levels and prevent waterlogging. In addition to their use in drainage systems, non-woven geotextiles are also employed in filtration applications, where they are used to separate fine particles from liquids. Their versatility and effectiveness in these applications make them an indispensable tool in modern construction projects.

Comparing Non-Woven Geotextiles with Woven Alternatives

When comparing non-wwoven geotextiles with their woven counterparts, several key differences emerge that influence their suitability for various applications. One of the most notable distinctions is the production process. Woven geotextiles are created by interlacing threads in a traditional weaving pattern, resulting in a fabric with a regular grid-like structure. This gives woven geotextiles high tensile strength and resistance to elongation, making them ideal for applications that require reinforcement and load distribution. In contrast, non-woven geotextiles are produced through a random arrangement of fibers that are bonded together, resulting in a fabric with a more irregular and porous structure.

The structural differences between woven and non-woven geotextiles lead to variations in their performance characteristics. Woven geotextiles typically offer higher tensile strength and lower elongation, making them suitable for applications that require high load-bearing capacity, such as retaining walls and embankment reinforcement. Non-woven geotextiles, on the other hand, exhibit higher permeability and better filtration capabilities due to their porous structure. This makes them ideal for applications that require effective drainage and filtration, such as subsurface drainage systems and erosion control. The choice between woven and non-woven geotextiles ultimately depends on the specific requirements of the project and the desired performance characteristics.

Another important consideration when comparing woven and non-woven geotextiles is their environmental impact. Both types of geotextiles can be made from synthetic fibers such as polyester and polypropylene, which offer resistance to biological and chemical degradation. However, the production processes for woven and non-woven geotextiles differ in terms of energy consumption and resource use. Non-woven geotextiles often involve the use of recycled materials and can be produced using less energy-intensive processes, making them a more sustainable option in many cases. Additionally, their functional benefits, such as enhanced drainage and erosion control, contribute to the overall sustainability of construction projects by reducing the need for chemical stabilizers and other environmentally harmful interventions.

Installation Techniques and Best Practices

Proper installation of non-woven geotextiles is crucial to ensuring their effectiveness and longevity in construction applications. One of the key considerations during installation is the preparation of the site. The area where the geotextile will be installed should be cleared of any sharp objects, debris, and vegetation that could potentially damage the fabric. The surface should be smooth and free of irregularities to ensure uniform contact between the geotextile and the underlying soil. This helps to prevent the formation of voids and ensures that the geotextile can perform its intended functions effectively.

When installing non-woven geotextiles, it is important to ensure proper overlap between adjacent sheets. Overlapping is necessary to maintain continuity and prevent gaps through which soil or water can pass. The recommended overlap distance varies depending on the specific application and site conditions, but a common guideline is to use an overlap of at least 300 mm (12 inches). In areas with high hydraulic gradients or steep slopes, a larger overlap may be necessary to ensure stability. Securing the overlaps with pins or staples can further enhance the integrity of the installation and prevent movement during construction.

Another best practice for installing non-woven geotextiles is to avoid excessive tension during placement. Stretching the fabric too tightly can reduce its effectiveness by altering its structure and permeability. Instead, the geotextile should be placed with a slight amount of slack to accommodate any potential movement or settlement. This approach ensures that the geotextile can maintain its intended performance characteristics over time. Additionally, it is important to protect the geotextile from UV exposure and physical damage during installation and subsequent construction activities. Covering the geotextile with a layer of soil or aggregate as soon as possible after installation can help to protect it from these potential hazards.

Case Studies: Successful Use of Non-Woven Geotextiles

The use of non-woven geotextiles in the construction of a major highway project in Europe serves as a prime example of their effectiveness in enhancing road stability and longevity. In this project, non-woven geotextiles were installed as a separation layer between the subgrade and the aggregate base layer. The geotextiles prevented the intermixing of different soil layers, ensuring a stable foundation for the pavement. Additionally, their drainage capabilities helped to manage water infiltration, reducing the risk of water-induced damage. The result was a durable and resilient roadway that required less maintenance and provided long-term performance benefits.

Another notable case study involves the use of non-woven geotextiles for erosion control in a coastal protection project in Asia. The project aimed to stabilize a shoreline that was prone to erosion due to wave action and tidal forces. Non-woven geotextiles were installed on the slope of the shoreline, providing a protective layer that reinforced the soil and prevented erosion. The geotextiles were also used in conjunction with vegetation to promote the establishment of plant roots, which further enhanced soil stability. The use of non-woven geotextiles in this project not only prevented land loss but also contributed to the preservation of the coastal ecosystem.

In a large-scale landfill project in North America, non-woven geotextiles were used to enhance the stability and environmental performance of the landfill. The geotextiles were installed as a filtration layer to prevent the migration of fine particles into the drainage system, ensuring the continuous flow of leachate and preventing clogging. Additionally, the geotextiles provided reinforcement to the landfill cover system, preventing settlement and deformation. The use of non-woven geotextiles in this project demonstrated their versatility and effectiveness in addressing complex engineering challenges while minimizing environmental impact.

Future Trends in Non-Woven Geotextile Technology

As the construction industry continues to evolve, several emerging trends are shaping the future of non-woven geotextile technology. One of the most promising developments is the increased use of biodegradable and eco-friendly materials in the production of non-woven geotextiles. Researchers and manufacturers are exploring the use of natural fibers such as jute, coir, and hemp, which offer the potential for reduced environmental impact and enhanced sustainability. These biodegradable geotextiles can provide the necessary performance benefits while decomposing naturally over time, eliminating the need for removal and disposal.

Another significant trend is the integration of advanced manufacturing techniques such as 3D printing and nanotechnology in the production of non-woven geotextiles. These technologies allow for greater precision and customization, enabling the creation of geotextiles with tailored properties for specific applications. For example, nanotechnology can be used to enhance the filtration capabilities of non-woven geotextiles by incorporating nanoparticles that trap contaminants more effectively. Similarly, 3D printing can be used to create geotextiles with complex structures and patterns that optimize performance in challenging conditions.

The use of smart and responsive materials is also gaining traction in the field of non-woven geotextiles. These materials can adapt to changing environmental conditions, providing enhanced performance and durability. For instance, geotextiles that incorporate moisture-responsive polymers can adjust their permeability based on the level of water saturation, optimizing drainage and filtration. Similarly, geotextiles with self-healing properties can repair themselves in response to damage, extending their lifespan and reducing maintenance requirements. The development and adoption of these advanced materials hold the potential to revolutionize the use of non-woven geotextiles in construction.

Conclusion: Embracing Non-Woven Geotextiles for a Greener Future

The integration of non-woven geotextiles into construction projects represents a significant step towards achieving sustainability in the industry. These innovative materials offer a range of benefits that enhance the performance and longevity of infrastructure while minimizing environmental impact. From soil stabilization and erosion control to effective drainage and filtration, non-woven geotextiles provide essential support that contributes to the resilience and durability of construction projects. Their versatility and adaptability make them a valuable tool for engineers, architects, and contractors seeking to balance robust engineering with environmental responsibility.

As the construction industry continues to prioritize sustainability, the use of non-woven geotextiles is set to become even more widespread. The ongoing development of advanced materials and manufacturing techniques will further enhance the capabilities and performance of these geotextiles, opening up new possibilities for their application. By embracing non-woven geotextiles, the construction industry can not only improve the quality and efficiency of its projects but also contribute to a greener and more sustainable future.

In conclusion, non-woven geotextiles represent a transformative solution for the construction industry, offering a bridge between innovative engineering and environmental stewardship. By understanding and leveraging the benefits of these materials, construction professionals can drive positive change and build a more sustainable tomorrow. The journey towards a greener future in construction begins with the adoption of sustainable practices and materials, and non-woven geotextiles are at the forefront of this movement.